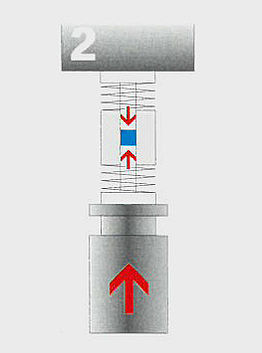

1. at room temperature and up to 300 °C

Single-action pressing of powdered substances

Model 8, 10 and 10 H

e.g.: potassium bromide, metal and ceramic powders, …

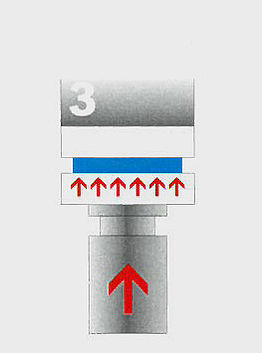

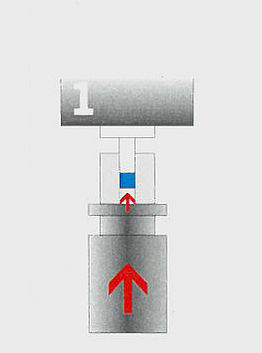

2. at room temperature

Double-acting pressing of powdered substances

Model 20

e.g.: potassium bromide, metal and ceramic powders, …

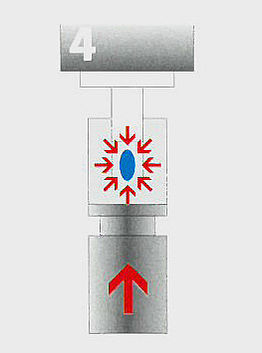

4. at room temperature

Cold-isostatic pressing of substances in all axial directions

KIP models

e.g. Graphite, ceramics, carbides, plastics, metal powders, ...

The modular design of the extensive P/O/WEBER programme for lab press technology constitutes a flexible system for the individual design of lab presses and pressing tools.

Starting with basic models, the best possible solution is created for each customer's specific problem. A variety of functional components, expansion modules and accessories are available for this purpose. In addition, P/O/WEBER also offers project development and one-off production of singular special applications.

We offer a wide range of experience and products for a variety of press-fitting applications in research, development, laboratory, quality assurance as well as industrial single and small batch production.

Today, P/O/WEBER presses – from manual to microprocessor-controlled lab presses – and P/O/WEBER press tools are in use worldwide.

Areas of application

- Industry (research and development, quality assurance, single and small batch production)

- Pharmaceutical industry

- Powder metallurgical laboratories

- Polymers and plastics-producing chemical industry

- Plastics processors

- Laboratories, institutes

Examples of use

- Sample preparation for X-ray fluorescence analysis

- Sample preparation in potassium bromide technology

- Preparation of oxidic and metallic samples for spectral analysis

- Inorganic and organic substances

- Powder tablets

- Mineral content of rock samples compressed into tablets

- Processing of high temperature materials

- Superconductors

- Carbon/graphite

- Plastics

- Refractory materials

- Ceramics

- Production of sintered metal pellets

- Sintered Materials

- Hard metal

- Powder metal

- Production of films made of plastics and polymers

- Production of sheets and composites from high-temperature-resistant plastics

- Production of compacts for visual inspection or physical testing of materials

- Production of fibre-reinforced resin mats

- Production of foils, sheets and planar composites