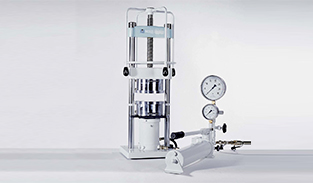

The 4-column electrohydraulic KIP lab presses are suitable for both cold isostatic pressing (KIP) and press trials with uniaxial pressing tools. For uniaxial pressing simply remove the ram and the press chamber from the press. The lab presses are therefore universally implementable and are suitable for a very wide range of trials and applications.

KIP lab presses allow substances to be pressed uniformly in all spatial axes simultaneously and are used both for the production of complex and simple compacts in econimical isostatic elastomer moulds. Different shapes and materials can be pressed simultaneously with several thousand bar in a hydraulic high-pressure tool, the so-called pressing chamber.

The homogeneous density of the cold isostatic compacts reduces internal stresses and thus, avoids cracks or layer formation. Greater green strength after pressing additionally offers good handling and processing options.

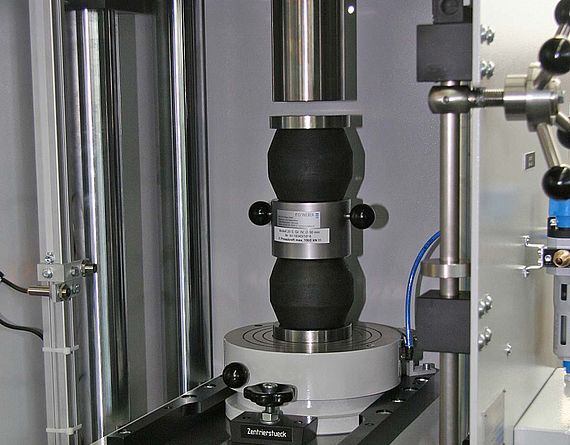

In cold isostatic pressing, the substances are filled in elastomer moulds and put in a liquid-filled press chamber. The press chamber is fixed on the workbench of the lab press and driven from below onto the die ram until the preselected press force is reached. The respective KIP model serves as a pressure intensifier, i.e. the system pressure of the hydraulic cylinder can be intensified at a constant ram force into a larger pressure in the press chamber.

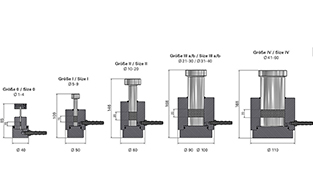

Decisive for this increase in pressure is the ratio of hydraulic cylinder piston surface to the surface of the press chamber bore. Different press chambers are available for each KIP-E series model, so that flexible reactions to different pressures and dimensions of the substance to be pressed are possible.

All press parameters can be set comfortably and very easily and the automatic operation of the pressing operations also allows continuous operation for larger quantities.

General

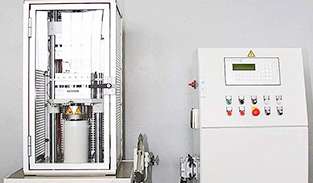

The KIP-E series electrohydraulic 4-column lab presses can be used universally as KIP and uniaxial presses. The series is very flexible and equipped with the latest easy-to-use control technology and pressure sensors.

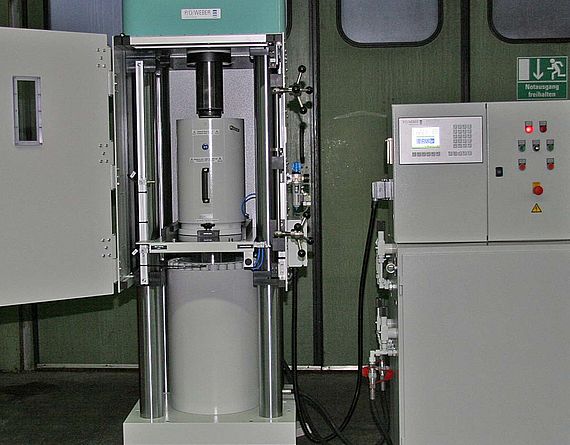

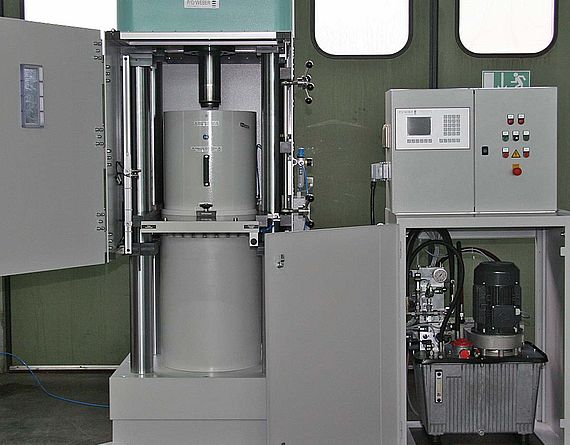

The 4-column construction is very robust and long-living. The press frame is built on a sturdy undercarriage and completely surrounded by a steel plate guard. The high-quality, double-acting hydraulic cylinder is installed on the base plate of the press and moves the workbench with press chamber upwards.

The electrohydraulic supply station consists of electrical switchgear cabinet with control unit and hydraulic unit with valve assembly. All pneumatic components are housed compactly and safely in metal housing.

The programme is started by pressing the start button on the lab press electrical switchgear cabinet. Press sequences and press parameters can be preset. To evaluate the test data, the connection of a PC with evaluation software can be made via an Ethernet interface.

During entering of the press chamber in the ram, the base of the hydraulic tool, the so-called pressing chamber, is pneumatically pressurised. The press chamber is thus minimally raised from the workbench and centered very accurately with the die ram.

The scope of supply for the KIP lab presses includes 10 seals for the die ram and 20 litres of special high pressure fluid for the hydraulic high pressure tool.

The KIP-E series can be individually adapted to many user requirements and equipped with many add-on components.

Advantages

- Easy to use and simple control

- Simple, space-saving and uncomplicated construction

- Made completely of the highest quality components

- Solid and proven construction for long service life

- Robust, long-life press frame

- Hard chrome-plated, inductively hardened press columns

- Digital press force display on the controller with peak value memory

- Press force converted into press chamber internal pressure (kbar / MPa)

- Sheet metal safety guard with switch

- Individually adaptable to many user requirements

- Special versions with extensive options available

| Type | KIP 100 E | KIP 200 E | KIP 200 ES | KIP 300 E | KIP 500 E | |

| Ram force max. | [kN] | 1.000 | 2.000 | 2.000 | 3.000 | 5.000 |

| Piston stroke max. | [mm] | 200 | 200 | 250 | 250 | 250 |

| Working height min.-max. | [mm] | 400 – 600 | 400 – 600 | 570 – 820 | 570 – 820 | 580 – 830 |

| <b>Passage between the columns</b> | ||||||

| from the front | [mm] | 400 | 400 | 400 | 410 | 520 |

| from the side | [mm] | 180 | 270 | 270 | 340 | 390 |

| Piston retraction | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | |

| Height approx. | [mm] | 1.720 | 1.814 | 2.029 | 2.127 | 2.350 |

| Space required approx. | [kg] | 702 x 704 | 814 x 823 | 884 x 823 | 959 x 873 | 1.202x 1.043 |

| Weight (incl. press chamber) approx. | [mm] | 1.250 | 1.680 | 2.100 | 2.756 | 5.600 |

| Height of switchgear cabinet / EHV approx. | [mm] | 1.707 | 1.707 | 1.707 | 1.707 | 1.707 |

| Required space switchgear cabinet / EHV approx. | [mm] | 626 x 978 | 626 x 978 | 626 x 978 | 626 x 978 | 626 x 978 |

| Weight switchgear cabinet / EHV approx. | [kg] | 250 | 250 | 250 | 250 | 250 |

| Hydraulic unit 2-stage | X | X | X | X | X |

High pressure hydraulic tools for KIP-E

| Type | PK1 | PK1 | PK2 | PK2 | PK3 | |

| Bore-Ø / Internal pressure max. | ||||||

| Ø 40 mm | [kbar] | 7,961 | – | – | – | – |

| Ø 50 mm | [kbar] | 5,094 | – | – | – | – |

| Ø 60 mm | [kbar] | 3,537 | 7,074 | 7,074 | – | – |

| Ø 70 mm | [kbar] | 2,598 | 5,197 | 5,197 | 7,796 | – |

| Ø 80 mm | [kbar] | 1,989 | 3,979 | 3,979 | 5,968 | – |

| Ø 90 mm | [kbar] | – | 3,144 | 3,144 | 4,716 | 7,860 |

| Ø 110 mm | [kbar] | – | – | 2,105 | 3,157 | 5,261 |

| Ø 120 mm | [kbar] | – | – | 1,768 | 2,652 | 4,421 |

| Ø 160 mm | [kbar] | – | – | – | – | 2,486 |

| Drill depth approx. | [mm] | 260 | 260 | 400 | 400 | 400 |

| Usable drilling depth approx. | [mm] | 160 – 180 | 160 – 180 | 250 – 300 | 250 – 300 | 250 – 300 |

| Tool outer diameter-Ø | [mm] | 225 | 225 | 300 | 300 | 490 |

| Tool height | [mm] | 310 | 310 | 500 | 500 | 500 |

YOU WOULD LIKE A CONSULTATION?

We’d be glad to! Talk to us about your desired production and rely on our many years of experience and expertise in lab press technology.

Consistant further development characterizes our ability to innovate. At P/O/WEBER you benefit from many years of experience.

Learn more

There are many companies that value "Made in Germany" – as our references prove. See for yourself.

Learn more

Direct contact is important to you? Then you are exactly right here. Do not hesitate to contact us if you have questions or uncertainties. We'll be pleased to help you.

Learn more