Precision press tools with systematology – The P/O/WEBER press tool series offers a special range of various press tools for most purposes in a high quality which has been proven over decades.

The press tools are characterised by high functionality, reliability, long service life and flexible use of materials. P/O/WEBER press tools are in use thousand-fold in laboratories worldwide and provide the optimal solution for your individual task in research, development, quality assurance as well as in single and small batch production.

Benefit from our know-how and our modular product structure – broad product selection and flexible functional components.

General

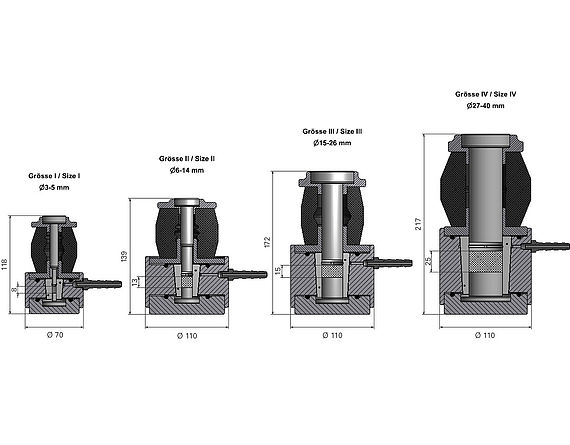

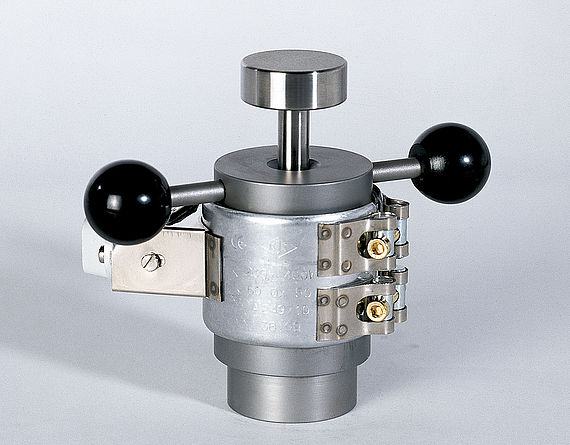

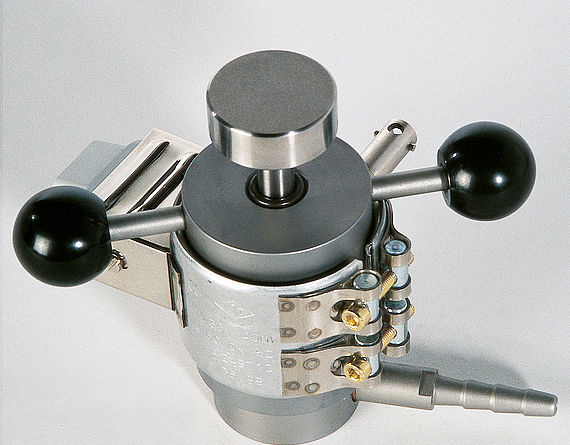

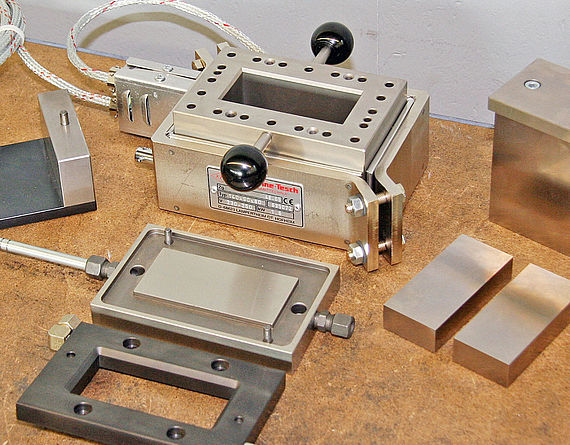

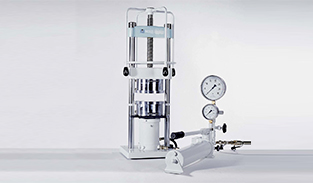

The Model 8 vacuum press tool has already proven itself thousands of times in laboratory practice worldwide. It is particularly valued for its all-round qualities and durable, robust construction. It is indispensable for the preparation of poorly soluble substances for infrared spectroscopy and X-ray fluorescence analysis.

Powdery substances are pressed between optically polished die surfaces to form a stable, plane-parallel, homogeneous compact. The compact is easy to remove from the press tool since the die is divided into two parts. The internal press parts and die are manufactured from high-alloy hardened tool steel.

Advantages

- Easy removal of the compacts thanks to ta divided press die

- Die interior inserts available in steps of 1 mm

- Universally applicable for many substances

- Optical polishing of the die ram front surfaces for high optical compact quality

- Can be used with and without vacuum

- Simple and rapid production e.g. of trasparent discs made from potassium bromide and other salts

- Optionally expandable with exchangeable and micro inserts

Options / Accessories

Exchangeable inserts for Model 8

In order to enable flexible use of the vacuum press tool Model 8, exchangeable inserts in the respective size can be individually supplemented. A exchangeable insert consists of upper die with top plate, lower die, die interior components and plunger.

Micro-inserts for Model 8

For the production of rectangular compacts, the substance requirement is only 20%, at consistant optical quality.

Available in the sizes:

for type size I 5 x 1 mm

for type size II 13 x 2 mm

for type size III 25 x 5 mm

for type size IV 40 x 10 mm

General

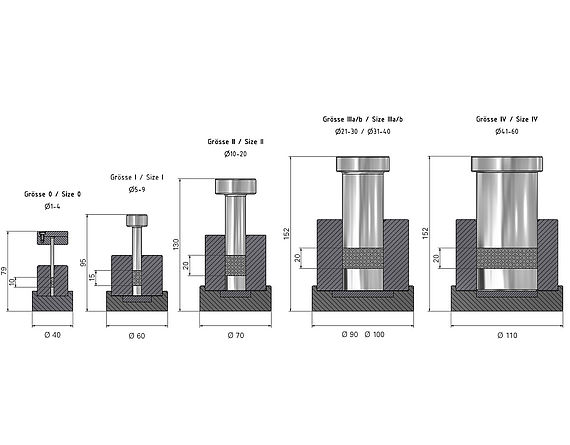

The Model 10 press tool offers an optimised price-performance ratio due to its simple and uncomplicated construction. It offers a long service life with easy handling due to the stable and solid construction in conjunction with high-quality material quality.

The Model 10 press tool is versatile for many substances and the selection of different die shapes and sizes allows the production of round, square, rectangular or ring-shaped compacts among others.

The press die and ram are made of high-alloy, hardened tool steel. Powdery substances are pressed in the press die between the optically polished and finely ground die surfaces to form a stable, plane-parallel, homogeneous compact.

Advantages

General

The Model 10 Vacuum press tool is based on the simple, uncomplicated design of the Model 10 Standard press tool. Unlike the Model 8 Vacuum press, it is not equipped with a divisible press die and exchangeable inserts.

The ease of use as well as the stable and solid construction of the proven standard Model 10 press tool remain, as well as the optimised price-performance ratio.

The press die and ram are made of high-alloy, hardened tool steel. The die is equipped with vacuum equipment for the connection of a vacuum pump.

Powdery substances are pressed in the press die between the optically polished and finely ground die surfaces to form a stable, plane-parallel, homogeneous compact.

Advantages

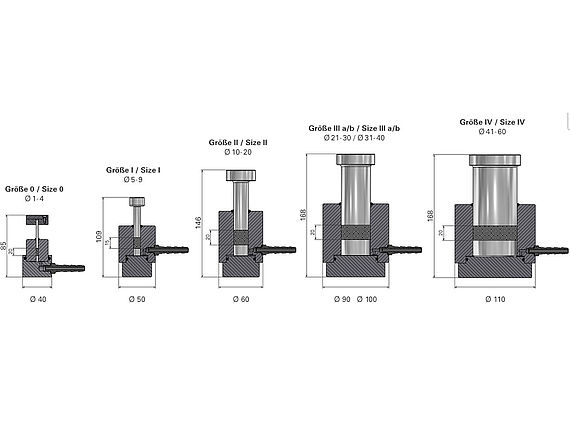

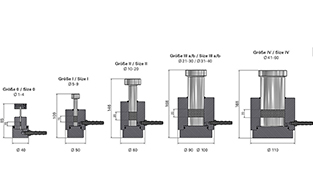

| Type size | 0 | I | II | III.a | III.b | IV | |

| Compact size | [ø mm] | 1 – 4 | 5 – 9 | 10 – 20 | 21 – 30 | 31 – 40 | 41 – 60 |

| Filling level max. | [mm] | 10 | 15 | 20 | 20 | 20 | 20 |

| Total height | [mm] | 85 | 109 | 146 | 168 | 168 | 168 |

| Outer diameter without heating tape | [mm] | 40 | 50 | 60 | 80 | 90 | 110 |

| Total weight approx. | [kg] | 0,5 | 1,0 | 2,1 | 5,5 | 5,5 | 8,8 |

| Optical polish | x | x | x | x | x | + |

General

In addition to normal cold pressing, the Model 10 H Hot press tool enables the production of compacts at temperatures of up to 300 °C (optionally 400 °C). With vacuum equipment, temperatures of up to max. 180 °C can be reached.

Handles and a temperature sensor can be attatched to the die which is girdled by a ceramic-insulated strip heater. The strip heater is connected to the TRG 1 temperature control unit and constantly regulated.

The Model 10 hot press tool is versatile for many substances, and the selection of different die shapes and sizes allows the production of round, square or rectangular compacts among others.

The press die and ram are made of high-alloy, hardened tool steel. For better handling, the Model 10 H hot press tool is equipped with a second short die ram.

Advantages

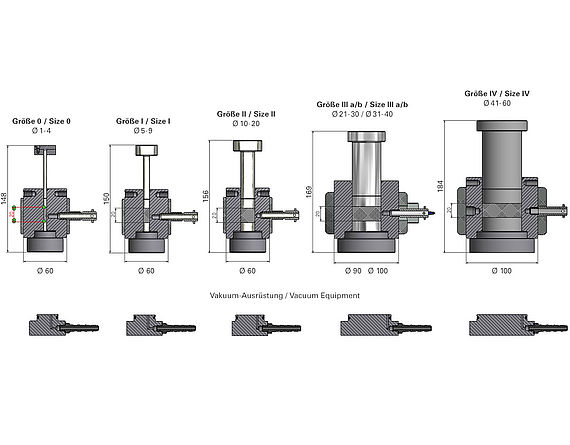

| Type size | 0 | I | II | III.a | III.b | IV | |

| Compact size* | [ø mm] | 1 – 4 | 5 – 9 | 10 – 20 | 21 – 30 | 31 – 40 | 41 – 60 |

| Filling level max. | [mm] | 20 | 20 | 20 | 20 | 20 | 20 |

| Total height | [mm] | 148 | 150 | 156 | 169 | 169 | 1847 |

| Outer diameter without heating tape | [mm] | 60 | 60 | 60 | 80 | 90 | 100 |

| Total weight approx. | [kg] | 3,1 | 3,2 | 3,4 | 8,6 | 8,6 | 11,9 |

| Optical polish | x | x | x | x | x | + | |

| Strip heater | x | x | x | x | x | x | |

| Heating regulation | TRG 1 | TRG 1 | TRG 1 | TRG 1 | TRG 1 | TRG 1 |

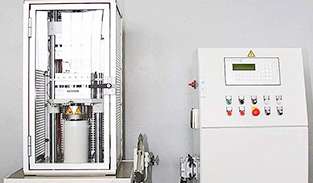

General

The temperature control unit TRG 1 is required for heating and for the temperature regulation of the Model 10 H hot press tools. The TRG 1 is equipped with a digital temperature controller and a temperature sensor PT 100.

The device is manufactured in desktop design and can be used for all P/O/WEBER hot press tools.< The temperature regulator is equipped with ACTUAL/TARGET setting display, PID control characteristics and additional analogue measurement value output.

Advantages

| Model | TRG 1 | |

| Display area | [°C] | 0 – 300 (optional 0 – 400) |

| No. of controllers | [pcs] | 1 |

| Controller type | [mm] | microprocessor-controlled two-point controller for heating with PID control characteristics |

| Control display | digital actual/set value display | |

| No. of temperature sensors | [pcs] | 1 |

| Temperature sensor type | PT 100 | |

| No. of measurement outputs | 1 | |

| Measurement output type | Analog, 0/4...20 mA | |

| Size L x W x H approx. | [mm] | 300 x 300 x 210 |

| Weight approx. | [kg] | 9 |

| Supply voltage | [VAC] | 230 |

| Nominal frequency | [Hz] | 50 |

| Connected load approx. | [kW] | 1,25 |

| Connected current approx. | [A] | 6 |

General

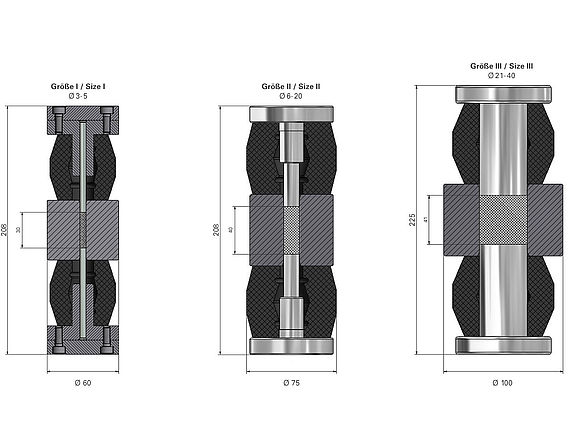

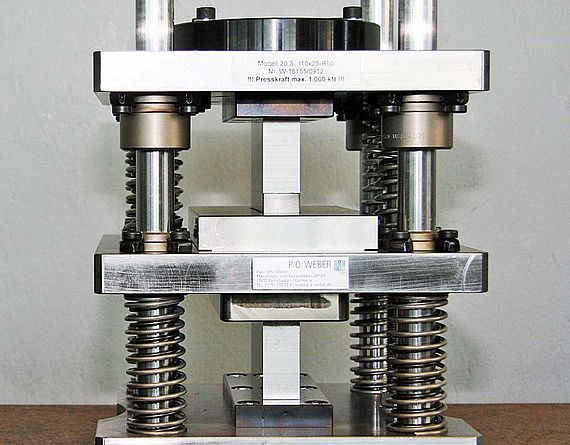

The double-acting Model 20 press tool is designed to meet the highest demands for homogeneity and stability of the compacts. In the special design of a floating die mounted on rubber springs with two dies working in opposite directions, the ram force is very even in both directions.

The Model 20 press tool is versatile for many substances and the selection of different die shapes and sizes allows the production of round, square or rectangular compacts among others.

The press die, ram and plunger are manufactured from high-alloy, hardened tool steel. Powdery substances are pressed in the press die between the optically polished die surfaces to form a stable, plane-parallel, homogeneous compact.

Advantages

General

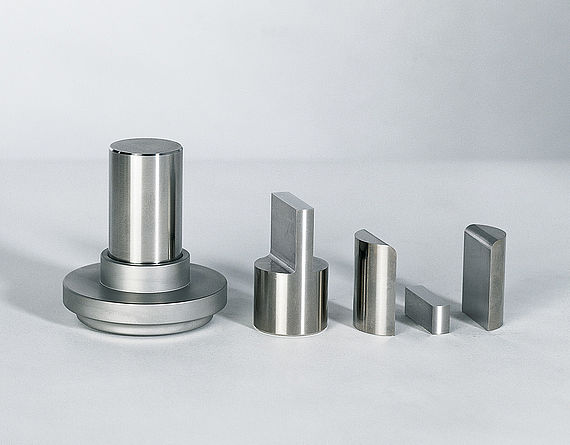

P/O/WEBER offers a comprehensive and flexible basic program for press tools with a variety of functional components, expansion modules and accessories for the optimal solution of individual tasks in laboratory practice.

In addition, P/O/WEBER also designs and manufactures custom-made products to customer specifications. They can draw on the immense wealth of experience over decades regarding special press tools and the best solution can be implemented.

The images demonstrate some practical examples.

YOU WOULD LIKE A CONSULTATION?

We’d be glad to! Talk to us about your desired production and rely on our many years of experience and expertise in lab press technology.

Consistant further development characterizes our ability to innovate. At P/O/WEBER you benefit from many years of experience.

Learn more

There are many companies that value "Made in Germany" – as our references prove. See for yourself.

Learn more

Direct contact is important to you? Then you are exactly right here. Do not hesitate to contact us if you have questions or uncertainties. We'll be pleased to help you.

Learn more