The lab press series PW is recommended for frequently changing pressing tasks in small to medium quantities, which can still be handled manually and when using different types of pressing tools. These models are very easy to use, extremely robust and can be placed on lab benches, workbenches or press trolleys.

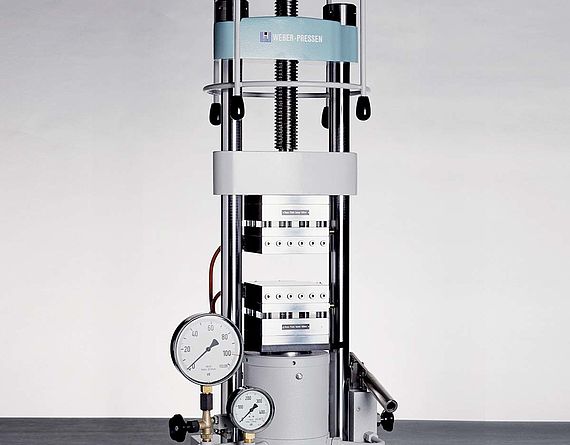

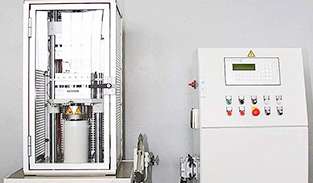

The manual 2-column laboratory presses of the PW series could be described as the classics of lab press technology, which have been optimised over decades.

The press tool or material is centered on the lower pressure plate and the upper pressure plate is rotated down with the adjusting spindle until it rests against the pressing material. The hydraulic pressure generated by operation of the manual pump causes the piston in the hydraulic cylinder to extend upwards. The pressure load and thus the system ram force is displayed directly on the manometer in kN and is unable exceed the permissible maximum value thanks to the adjustable pressure relief valve.

Other outstanding features include the hydraulic cylinder with integrated oil tank, the hard chrome-plated press columns, the plasma-hardened adjusting spindle with trapezoidal thread and the double-acting manual pump, which generates hydraulic pressure during both the downward and the upward movement of the pump lever.

The PW series can be individually adapted to many user requirements and equipped with many add-on components.

All the PW series lab presses are also available with heating/cooling plate systems up to 300 °C or 500 °C. Furthermore, the lab presses can also be equipped for installation in glove boxes and can be retrofitted for combined manual and automatic operation with an electrohydraulic supply.

General

The PW series manual 2-column lab presses are the classics of lab press technology. The lab presses, which have been optimised over decades, are characterised by their easy handling and extremely robust design.

The 2-column construction is very compact and space-saving. The press frame consists of a base plate, two hard chrome-plated columns and the press yoke. An adjusting spindle with trapezoidal thread is attached to the press yoke which serves to apply the upper pressure plate quickly to the pressing material or pressing tool. Thus, direct pressure must only be applied via the hydraulic manual pump.

Centered on the base plate is the hydraulic cylinder with adjustable pressure-limiting valve and integrated oil reservoir. The pressure is built up by the hydraulic hand pump on the right side of the base plate. The manual pump can also be mounted outside the box for installation in the glove box, regardless of the press frame.

The PW series can be individually adapted to many user requirements and equipped with many add-on components.

Advantages

- Easy to use

- Space-saving and uncomplicated construction

- Made completely of the highest quality components

- Solid and proven construction for long service life

- Hard chrome-plated press columns

- Double-acting manual pump

- Plasma-hardened adjusting spindle with trapezoidal thread

- Direct press force display by pressure gauges with scaling in kilonewtons [kN]

- Individually adaptable to many user requirements

- Special versions with extensive options available

Options / Accessories

- With spindle-adjustable column-guided crossbeam

- Low power second manometer

- Column-guided workbench

- Security guard

- Increased working height

- Enlarged column passage

- Hardened press plates

- Mobile press trolley

- Digital display PRESSTRONIC

- Pressure sensor

- Automatic switchover valve

- Electrohydraulic power unit WHC

- Supply station EHV

- Adaptation for glove box

- Pulled down selector fork

| Type | PW 10 | PW 20 | PW 40 | PW 100 | |||

| Ram force max. | [kN] | 130 | 200 | 450 | 1.000 | ||

| Piston stroke max. | [mm] | 50 | 50 | 50 | 75 | ||

| Adjustment range spindle approx. | [mm] | 130 | 130 | 130 | 190 | ||

| Working height min.-max. | [mm] | 60 – 240 | 60 – 240 | 60 – 240 | 0 – 260 | ||

| Passage between the columns | [mm] | 192 | 222 | 212 | 270 | ||

| Height with extended spindle approx. | [mm] | 828 | 843 | 924 | 1.269 | ||

| Space required approx. | [mm] | 366 x 433 | 380 x 489 | 402 x 489 | 536 x 621 | ||

| Weight approx. | [kg] | 71 | 104 | 159 | 375 | ||

| Piston retraction | with spring | with spring | with spring | with spring | |||

| Column guided crossbeam | + | + | + | x | |||

| Automatic switchover valve | + | + | + | x |

General

The series PW-H lab presses are equipped with round or rectangular heating/cooling plate systems HKP and the appropriate temperature control units TRG. Round heating/cooling plate systems are heated with surface radiators up to 300 °C, rectangular HCPs are designed with high-performance heating cartridges and can reach temperatures of up to 500 °C. In order to mount the upper heating/cooling plate system, all lab presses with heating/cooling plate system are equipped with an adjustable crossbeam guided in both press columns.

The heating/cooling plate systems are equipped with a cooling circuit for press cooling and two cooling circuits for cooling the upper and lower heating plate. The system’s pressure plates are made of hardened, high-pressure-resistant, fine-ground tool steel.

The separate heating of the upper and lower heating plates is achieved via the TRG temperature control units. The TRGs are each equipped with a digital controller and temperature sensor for each heating plate.

The PW-H series can be individually adapted to many user requirements and equipped with many add-on components.

Advantages

- Simple, space-saving and uncomplicated construction

- Made completely of the highest quality components

- Solid and proven construction for long service life

- Easy to use

- Individually adaptable to many user requirements

- Special versions with extensive options available

- Separate control of upper and lower heating plates

- Heating plates high pressure resistant

Options / Accessories

- With spindle-adjustable column-guided crossbeam

- Low power second manometer

- Column-guided workbench

- Security guard

- Increased working height

- Enlarged column passage

- Hardened press plates

- Mobile press trolley

- Digital display PRESSTRONIC

- Pressure sensor

- Automatic switchover valve

- Electrohydraulic power unit WHC

- Supply station EHV

- Adaptation for glove box

- Pulled down selector fork

- HKP300-ø200 mm

- HKP300-ø220 mm

- TRG2 as special version

| Type |

PW 10 H HKP300-ø165 |

PW 20 H HKP300-ø165 |

PW 40 H HKP300-ø165 |

PW 100 H HKP300-ø165 | |

| Ram force max. | [kN] | 130 | 200 | 450 | 1.000 |

| Piston stroke max. | [mm] | 50 | 50 | 50 | 75 |

| Adjustment range spindle approx. | [mm] | 130 | 130 | 130 | 190 |

| Working height min.-max. | [mm] | 0 – 180 | 0 – 180 | 0 – 180 | 0 – 240 |

| Passage between the columns | [mm] | 192 | 222 | 212 | 270 |

| Height with extended spindle approx. | [mm] | 971 | 986 | 1.087 | 1.410 |

| Space required approx. | [mm] | 366 x 433 | 380 x 489 | 402 x 489 | 536 x 621 |

| Weight approx. | [kg] | 104 | 142 | 207 | |

| Piston retraction | with spring | with spring | with spring | with spring | |

| Column guided crossbeam | x | x | x | x | |

| Automatic switchover valve | + | + | + | x |

|

Temperature control unit TRG2 | ||

| Supply voltage | [VAC] | 230 |

| Connection power approx. | [kw] | 2 |

| Connection current approx. | [A] | 9 |

| Fuse max. | [A] | 16 |

| Rated frequency | [Hz] | 50 |

| Dimensions approx. | [mm] | 300 x 380 x 210 |

| Weight approx. | [kg] | 12,2 |

| Number of temperature sensors PT100 | [pcs] | 2 |

| Number of digital controllers with setpoint/actual display | [pcs] | 2 |

General

The series PW-H lab presses are equipped with round or rectangular heating/cooling plate systems HKP and the appropriate temperature control units TRG. Round heating/cooling plate systems are heated with surface radiators up to 300 °C, rectangular HCPs are designed with high-performance heating cartridges and can reach temperatures of up to 500 °C. In order to mount the upper heating/cooling plate system, all lab presses with heating/cooling plate system are equipped with an adjustable crossbeam guided in both press columns.

The heating/cooling plate systems are equipped with a cooling circuit for press cooling and two cooling circuits for cooling the upper and lower heating plate. The system’s pressure plates are made of hardened, high-pressure-resistant, fine-ground tool steel.

The separate heating of the upper and lower heating plates is acheived via the TRG temperature control units. The TRGs are each equipped with a digital controller and temperature sensor for each heating plate.

The PW-H series can be individually adapted to many user requirements and equipped with many add-on components.

Advantages

- Simple, space-saving and uncomplicated construction

- Made completely of the highest quality components

- Solid and proven construction for long service life

- Easy to use

- Individually adaptable to many user requirements

- Special versions with extensive options available

- Separate control of upper and lower heating plates

- Heating plates high pressure resistant

Options / Accessories

- With spindle-adjustable column-guided crossbeam

- Low power second manometer

- Column-guided workbench

- Security guard

- Increased working height

- Enlarged column passage

- Hardened press plates

- Mobile press trolley

- Digital display PRESSTRONIC

- Pressure sensor

- Automatic switchover valve

- Electrohydraulic power unit WHC

- Supply station EHV

- Adaptation for glove box

- Pulled down selector fork

- HKP500-200x200 mm

- HKP500-220x220 mm

- TRG3 as special version

| Type |

PW 10 H HKP500-160x160 |

PW 20 H HKP500-160x160 |

PW 40 H HKP500-160x160 |

PW 100 H HKP500-160x160 | |

| Ram force max. | [kN] | 130 | 200 | 450 | 1.000 |

| Piston stroke max. | [mm] | 50 | 50 | 50 | 75 |

| Adjustment range spindle approx. | [mm] | 130 | 130 | 130 | 190 |

| Working height min.-max. | [mm] | 0 – 180 | 0 – 180 | 0 – 180 | 0 – 240 |

| Passage between the columns | [mm] | 192 | 222 | 212 | 270 |

| Height with extended spindle approx. | [mm] | 1.070 | 1.090 | 1.191 | 1.499 |

| Space required approx. | [mm] | 397 x 433 | 399 x 489 | 402 x 489 | 536 x 621 |

| Weight approx. | [kg] | ||||

| Piston retraction | with spring | with spring | with spring | with spring | |

| Column guided crossbeam | x | x | x | x | |

| Automatic switchover valve | + | + | + | x |

|

Temperature control unit TRG3 | ||

| Supply voltage | [VAC] | 400 |

| Connection power approx. | [kw] | 6,5 |

| Connection current approx. | [A] | 10 |

| Fuse max. | [A] | 16 |

| Rated frequency | [Hz] | 50 |

| Dimensions approx. | [mm] | 300 x 380 x 210 |

| Weight approx. | [kg] | 14,5 |

| Number of temperature sensors PT100 | [pcs] | 2 |

| Number of digital controllers with setpoint/actual display | [pcs] | 2 |

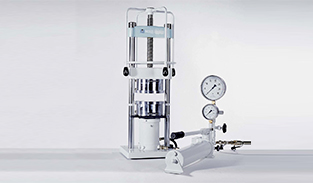

General

The PW-BOX series lab presses are specially designed for use in glove boxes. The 2-column press frame and the hydraulic cylinder are based on the basic version of the PW series. However, the complete hydraulic manual pump with pressure-limiting valve, pressure gauge and oil reservoir is mounted outside the glove box. The connection from the manual pump to the hydraulic cylinder is acheived with high-pressure hydraulic hoses, the passage through the wall of the glove box is very easy thanks to bulkhead fittings.

For better handling of the adjusting spindle in the glove box, it is usually recommended to use the selector fork. By turning the selector fork with the adjusting spindle, only the upper pressure plate is applied to the press tool or press material. Pressure generation is very simply thanks to the external hydraulic manual pump. Should an oil change be necessary, this can be done directly on the oil reservoir of the external manual pump. Assembly work in the glove box is not necessary.

The PW-BOX series can be individually adapted to many user requirements and equipped with many add-on components. It is also possible to integrate heating/cooling plate systems, please contact us for your individual requirements!

Advantages

- Easy to use

- Space-saving and uncomplicated construction

- Made completely of the highest quality components

- Solid and proven construction for long service life

- Hard chrome-plated press columns

- Double-acting manual pump

- Plasma-hardened adjusting spindle with trapezoidal thread

- Direct press force display by pressure gauges with scaling in kilonewtons [kN]

- Individually adaptable to many user requirements

- Special versions with extensive options available

Options / Accessories

- With spindle-adjustable column-guided crossbeam

- Low power second manometer

- Column-guided workbench

- Increased working height

- Enlarged column passage

- Hardened press plates

- Digital display PRESSTRONIC

- Pressure sensor

- Automatic switchover valve

- Electrohydraulic power unit WHC

- Supply station EHV

- Adaptation for glove box

- Pulled down selector fork

| Type | PW 10-BOX | PW 20-BOX | PW 40-BOX | ||||

| Ram force max. | [kN] | 130 | 200 | 450 | |||

| Piston stroke max. | [mm] | 50 | 50 | 50 | |||

| Adjustment range spindle approx. | [mm] | 130 | 130 | 130 | |||

| Working height max. | [mm] | 240 | 240 | 240 | |||

| Passage between the columns | [mm] | 192 | 222 | 212 | |||

| Height with extended spindle approx. | [mm] | 828 | 843 | 924 | |||

| Space required approx. | [mm] | 360 x 320 | 376 x 376 | 376 x 376 | |||

| Weight without manual pump approx. | [kg] | 61 | 94 | 149 | |||

| Piston retraction | with spring | with spring | with spring | ||||

| External manual pump with oil tank/hydraulic hose | x | x | x |

General

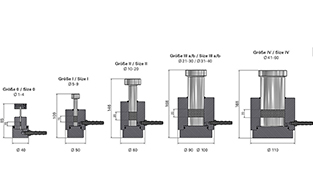

The PW-KIP series lab presses are equipped for use with hydraulic high-pressure tools for cold isostatic pressing (KIP). In cold-isostatic pressing, the material to be pressed is packed in a flexible silicone mold, sealed liquid-tight and then compressed at high pressure in all spatial directions simultaneously in the hydraulic fluid filled press tool.

The PW-KIP is equipped with a special workbench, on which the hydraulic high-pressure tool can be pulled very easily to the front for loading and unloading. For this purpose, the base of the tool is pressurised with compressed air, which allows easy sliding of the tool. The lab presses are equipped as standard with a safety guard and a pneumatic maintenance unit with pressure regulator, special high-pressure seals and special high-pressure liquid are included.

For standard uniaxial presses, the high-pressure tool and the die ram are simply removed, and the lab press can then be used flexibly with various press tools for standard press applications.

The PW-KIP series can be individually adapted to many user requirements and equipped with many add-on components.

Advantages

- Simple, space-saving and uncomplicated construction

- Made completely of the highest quality components

- Solid and proven construction for long service life

- Easy to use

- Individually adaptable to many user requirements

- Special versions with extensive options available

- High pressure can be achieved simultaneously in all spatial directions

- Also for uniaxial standard pressing applications

Options / Accessories

- With spindle-adjustable column-guided crossbeam

- Low power second manometer

- Column-guided workbench

- Increased working height

- Enlarged column passage

- Mobile press trolley

- Digital display PRESSTRONIC

- Pressure sensor

- Automatic switchover valve

- Electrohydraulic power unit WHC

- Supply station EHV

- High-pressure press tools in various designs

| Type | PW 40-KIP | ||||||

| Ram force max. | [kN] | 450 | |||||

| Piston stroke max. | [mm] | 50 | |||||

| Adjustment range spindle approx. | [mm] | 130 | |||||

| Working height max. | [mm] | 450 | |||||

| Passage between the columns | [mm] | 212 | |||||

| Height with extended spindle approx. | [mm] | 1.200 | |||||

| Space required approx. | [mm] | 600 x 620 | |||||

| Weight approx. | [kg] | 305 | |||||

| Piston retraction | with spring |

| Type | PK0-ø32 | PK0-ø40 | PK0-ø50 | PK0-ø70 | |||

| Bore diameter-ø | [mm] | 32 | 40 | 50 | 70 | ||

| Internal tool pressure max. | [kbar] | 5,60 | 3,58 | 2,29 | 1,17 | ||

| Bore surface | [cm²] | 8,04 | 12,57 | 19,63 | 38,48 | ||

| Drill depth approx. | [mm] | 210 | 210 | 210 | 225 | ||

| Usable drilling depth approx. | [mm] | 160 | 160 | 160 | 170 | ||

| Tool outer diameter-ø | [mm] | 135 | 135 | 135 | 135 | ||

| Tool height | [mm] | 260 | 260 | 260 | 260 |

YOU WOULD LIKE A CONSULTATION?

We’d be glad to! Talk to us about your desired production and rely on our many years of experience and expertise in lab press technology.

Consistant further development characterizes our ability to innovate. At P/O/WEBER you benefit from many years of experience.

Learn more

There are many companies that value "Made in Germany" – as our references prove. See for yourself.

Learn more

Direct contact is important to you? Then you are exactly right here. Do not hesitate to contact us if you have questions or uncertainties. We'll be pleased to help you.

Learn more